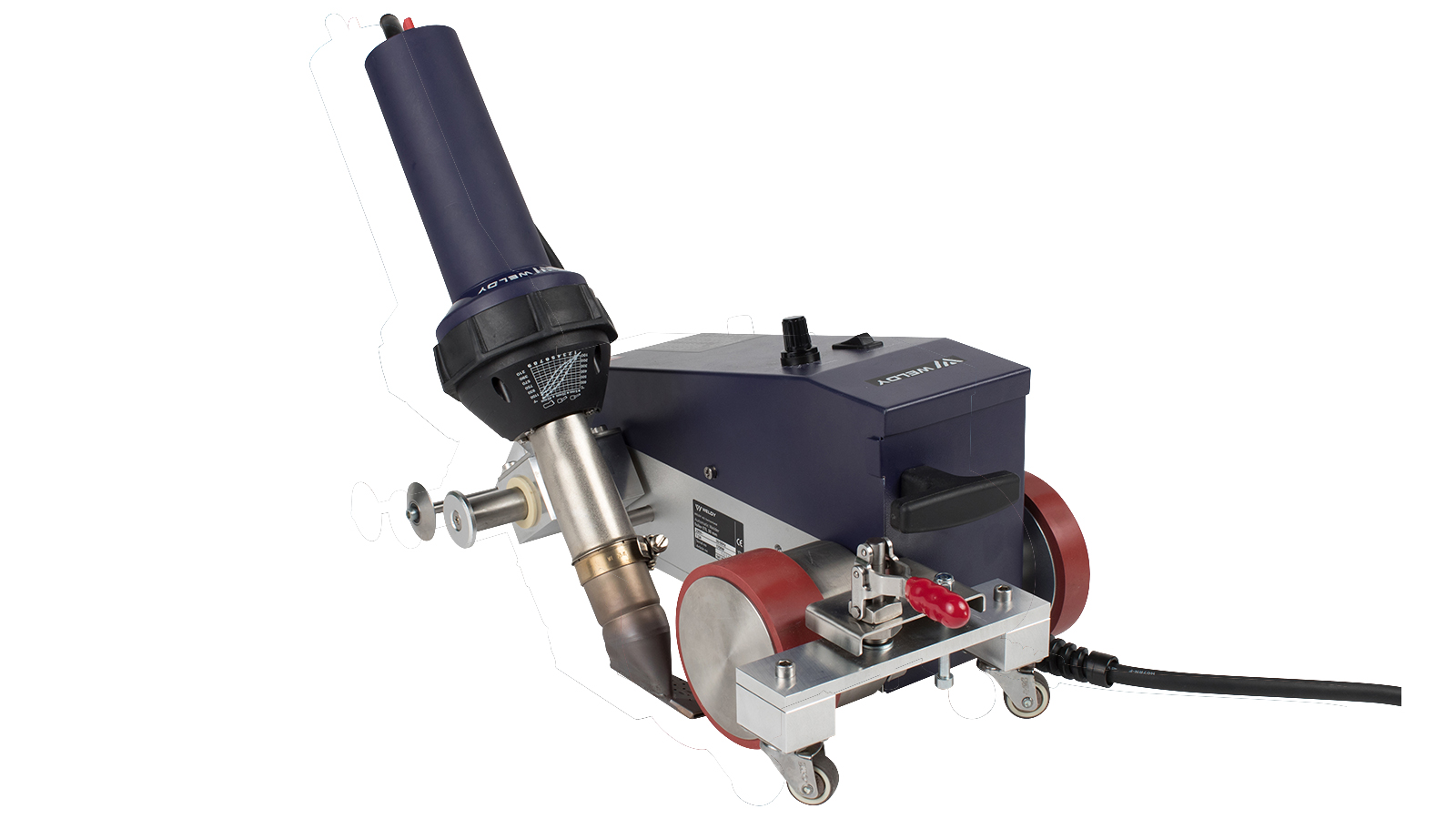

The foiler ensures simple and reliable welding of sheets and advertising banners. The weld seam width can be set to 20 or 30 mm as required. Thanks to the air volume and temperature control, you can adjust the welding settings to suit your needs. The foiler is your welding machine for individual welding applications.

The intuitive use and automatic start of this hot air machine makes welding sheets and advertising banners easy. The integrated guide roller ensures optimal track guidance for overlap welding and hem seams. Whether the materials are thick or thin, the foiler ETL offers you perfect welding of membranes and advertising banners.

This quick and lightweight welding machine is ideal for geomembranes from 0.5 to 1.5 mm thick (HDPE 0.4–1.0 mm; TPO 0.7–1.5 mm). The miniwelder geo2 can be used to weld fish farm and water tanks, in foundation sealing and many other industrial areas. The miniwelder geo2 distinguishes itself through its revolutionary drive technology and its intuitive use. Temperature and speed easily can be activated and deactivated by means of two buttons, and adjusted using two dials. The current process status is displayed by two LEDs.

Lightweight and easy to use. The miniwelder roof2 can be used on all pitched roofs and is ideal for all PVC and TPO inner roof membranes, up to 1 mm. The inner roof membrane does not flap when welding as the hot-wedge technology requires no blower air. Save money on toxic solvent-welding agents.

The miniwelder tex2 is ideal for thin materials. Thanks to the welder's optimized wedge geometry, the miniwelder tex2 welds 0.1 to 1.0 mm membranes perfectly. With the help of its revolutionary control system, welding start-up is child’s play. The welder is simple and intuitive to use. You will be convinced by the performance of the miniwelder tex2.

With the roofer RW3400, you obtain a high welding performance at a low price The overlap welding machine is ideal for all thermoplastic membranes up to 1.8 mm. With its automatic start-up system and ease of use, the RW3400 guarantees reliable welds.